ASSIST4RESILIENCE: Increasing Resilience in Manufacturing – Development of a Digital Twin Based Worker Assistance

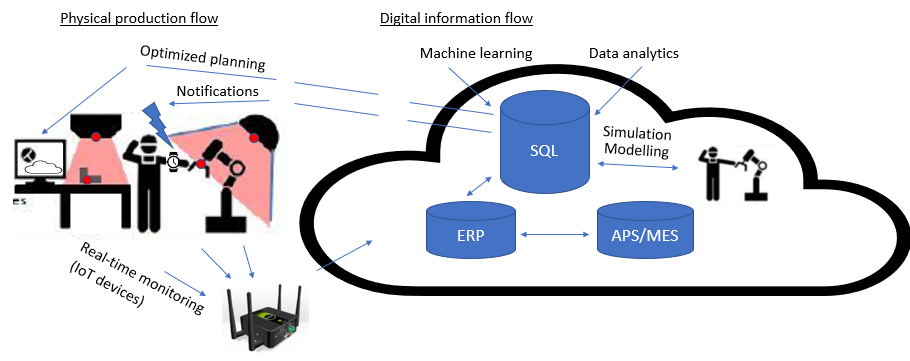

The project aims to increase resilience in human-centered SME manufacturing companies by merging cognitive assistance supported workstation with a real-time connected Digital Twin that enables real-time optimization of a digitalized workstation and related work processes through safe human-machine interactions.

The main steps of the research:

- practically usable resilience metrics analysis and evaluation for manufacturing,

- Axiomatic Design decomposition for resilient Cyber-Physical Production Systems design,

- approach for monitoring system architecture for long-term resilience,

- Digital Twin integration with worker assistance and information systems,

- cyber-physical demonstrator design, testing and validation.

Team

Dr. Tanel Aruväli

Senior Research Fellow

Free University of Bozen-Bolzano, Smart Mini Factory Laboratory

tanel.aruvaeli@unibz.it

Prof. Dr.-Ing. Dipl.-Wirtsch.-Ing. Erwin Rauch

Endowed Professor for Smart and Sustainable Manufacturing

Free University of Bozen-Bolzano, Smart Mini Factory Laboratory

Journal articles

Conference publications

Conference publications (accepted, in print)

Aruväli, T., De Marchi, M. & Rauch, E. Monitoring System Architecture for Long-Term Resilience in Manufacturing. Modern Materials and Manufacturing (MMM2023), AIP Publishing, 2023.

For further research collaborations, please contact tanel.aruvaeli@unibz.it

This project is financed by the Autonomous Province of Bozen/Bolzano, Department innovation, research, universities and museums.